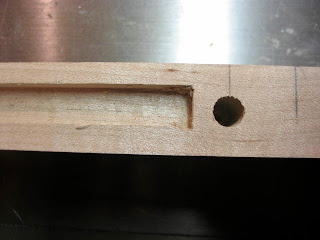

Yesterday the dados were cut in the frame rails and stiles. Since there's a center stile (which has already been doweled to the top and bottom rails), the dados needed to be "stopped". The round slot cutter leaves an arching cut at the end of it's travel, so the stopped dadoes need to be squared up by hand. The panel will conceal them, so appearance isn't important.

The panels are more than 24" wide, and all 4 together consume almost 8' of length. This means there's no room for "spares" in one ($95!!) sheet of plywood. Hardboard is cheap, so templates were made to tweak the fit - a good thing, too, since some planing and fitting was required.

Not having enough hardboard of sufficient width to make the templates, the table saw cover was sacrificed. Obviously it was well-used and ready to be replaced, so it was cut up to make the template for the large panel. Since both assemblies are symmetrical, only one of each size is needed - but fit was verified in both sides just to make sure before cutting up the spendy stuff.

The frames are finally filled with panels.

Monday, January 28, 2008

Panels

Frame dadoes

Sunday, January 13, 2008

Wednesday, January 2, 2008

Final version

I found dimensions on Thomasville's website and tweaked this a little more. The footboard is now a little larger - it reaches closer to the floor. The bottom edge of the rails is closer to the bottom edge of the headboard. The bottom of the mattress sits 1" below the top edge of the rails. The headboard and footboard heights match the T-ville version. The post caps still aren't pictured, but th ey will add a little less than 3"to the height of the posts.

With all these changes, the top of the mattress is now about 26".

T-ville's version has the slats 10" off the floor, so a boxspring would be required. This version has the bottom edge of the rail 10" off the floor, and the platform 7 1/2" above that (the rails are 8 1/2" wide).

Note that the footboard intercepts the mattress a bit.